|

| |

|

| |

|

| |

Ever since its beginning in 1963, Speroni has always applied the precision by design motto in all its work; each and every product that leaves its factory incorporates this. The development of Speroni product is based on the fact that its systems are means of production and as a result it has to produce tangible economic advantages for its customers.

After more than 50 years in the development and manufacturing of Tool Presetting and Measuring systems and of Inspection Robots (CMMs) for the geometrical measurement of machined parts in a shop floor environment, Speroni is still convinced that it has to continue to maintain the quality and originality of its solutions guided by the needs of its customers. |

|

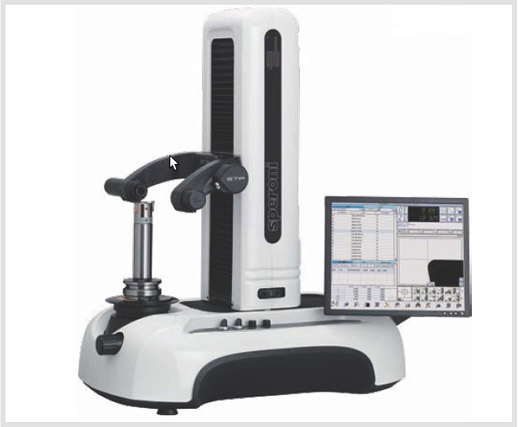

STP Magis |

| |

|

|

| no better & easier way to improve your process |

The new STP MAGIS generation of tool presetting and measuring system has revolutionized the value of entry level tool measurement. The innovative MAGIS control delivers all of the needed measuring features and functions in a user friendly, clean and trouble-free single screen user interface.

As for all of the SPERONI Tool Presetting & Measuring Systems, the structure of MAGIS is completely made of aged pearlitic cast iron in order to guarantee the best thermal stability.

Contrasting most presetter designs, the homogeneous structure of MAGIS resolves all of those issues one encounters on systems which use light alloys and/or granite that have a different and unstable reaction to changes in the temperature and the environment.

Homogeneity is a key design element which has been proven on SPERONI systems for now over 50 years and in the metalworking field for even longer. |

| |

|

|

| Highlights: |

| |

|

|

Homogeneous structure |

|

|

|

|

Compact size |

|

|

|

|

Unparalleled precision |

|

|

|

|

Heidenhain® glass scales |

|

|

|

|

Schneeberger® linear guideways |

|

|

|

|

Sony® CCD cameras |

|

|

|

|

Marcel Aubert® optics |

|

|

|

|

Festo® Pneumatics |

|

|

|

|

Brand PC based controls |

|

|

|

|

SPERONI original spindle system |

|

|

|

|

Unrivaled price/performance ratio |

|

|

|

|

Manual operation, automatic mechanical clamping, cnc spindle |

|

|

|

|

Data output (post processor) and network connection |

|

|

|

|

| |

| The solid design, together with Speroni's excellence in manufacturing, eliminates the need for frequent recalibration due to changes in temperature during the work shift; as well as guaranteeing the precision and repeatability of your system year after year. Due to this fact, software compensation – as offered by other presetter manufacturers – is not needed in order to compensate for misalignment. |

| |

| Features: |

|

|

| rapid axis movement |

precision ground integrated spindle calibration edge |

ergonomically

designed X axis and Z

axis fine adjustmen |

ergonomically

designed LCD monitor support arm |

industrial grade

controls for the spindle disk brake system |

Heidenhain® glass

scales, Schneeberger® guideways |

|

| Software: |

| |

|

|

Single window graphical interface |

|

|

|

|

|

Flying crosshair |

|

|

|

|

|

45X standard magnification |

|

|

|

|

Over 150 measuring icons |

|

|

|

|

Tool management for 1,000 tools |

|

|

|

|

Adapter & zero point management |

|

|

|

|

Print management |

|

|

|

|

Dial indicator and run-out functions |

|

|

|

|

MaxP function |

|

|

|

|

Full screen function & zoom to 120X |

|

|

|

|

Base Post Processor |

|

|

|

|

Data backup function |

|

|

|

|

Autofocus function |

|

|

|

| |

|

|

| MAGIS |

EDGE 2.0 |

EDGE PRO |

| |

|

| |

|

|

The new MAGIS control is the most intuitive and easy to use vision

system on the market today. |

The new EDGE 2.0 PC-based control and image processing system is the complete upgradable control for tool management, user management, tool inspection and CAM interfacing. |

The new EDGE PRO control is the most intuitive and easy to use vision system on the market today. |

| |

|

|

| more information > |

more information > |

more information > |

|

|

| |

| |

|

|

| Technical Data: |

Standard Eqipment: |

|

snap gage |

max Ø |

max H |

| MAGIS 400 |

50 mm |

350 mm |

400 mm |

| MAGIS 500 |

50 mm |

350 mm |

500 mm |

| MAGIS 600 |

50 mm |

350 mm |

600 mm |

|

|

|

integral spindle high precision |

|

|

|

|

|

spindle disk brake |

|

|

|

|

|

integrated calibration master |

|

|

|

|

fine adjustment X & Z axis |

|

|

|

|

precision +/- 2µ |

|

|

|

|

| |

|

| |

| |

|

|